Injection plastic molding is one of the most popular methods of manufacturing and manufacturing plastic parts such as auto parts and home appliances. In fact, the possibility of mass production of plastic parts, precision and elegance, cost -effective costs, diversity of construction and…

What is Molding?

Molding is referred to as the molding process and is one of the most used industries in Iran. The format is a tool that puts a body -shaped body inside or outside and model it. The constituent tool is called a piece and is called the molding process and the molding process.

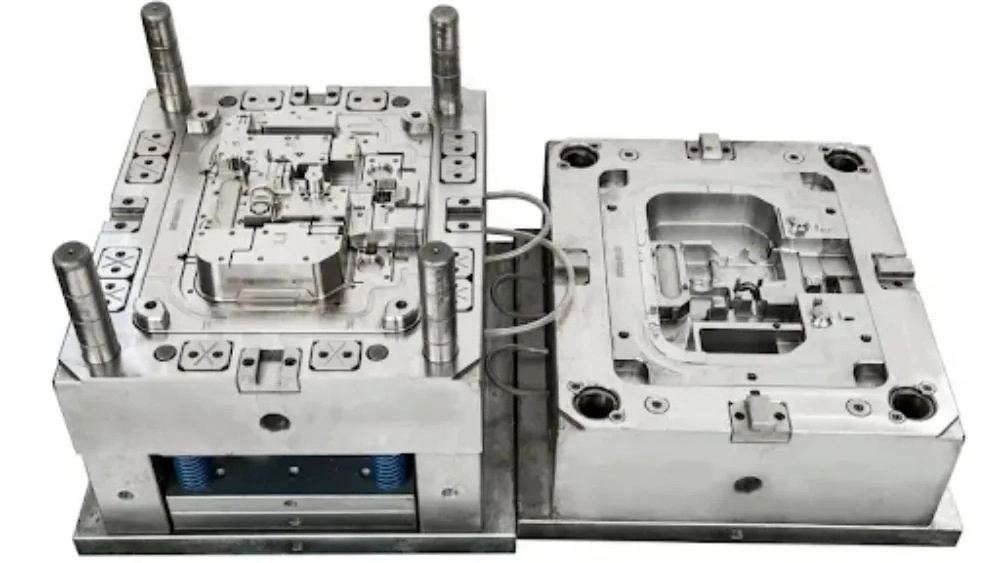

Plastic injection molds

This method is known as the best and most practical way to produce plastic parts. Plastic injections are mainly made of steel and have complex technology to build, thus the cost of making these molds is high. Heat the thermoplast, then pour into the cold mold and, after enriching the desired form, is difficult to decrease with the desired heat.

Simultaneous production of multiple products over a period of time has made this type of molding a favorable option for mass production.

Types of plastic injection molds:

1. Cold Plastic Injection Molds

2. % Plastic Injection Molds with Hot Walking $@|

The piece to be made by plastic injection must be designed according to the standards and structure of this method. After the veil is sampled in several stages, and after evaluation and modification, the mold is made. Pre -mold sampling is one of the important steps for making a piece that prevents time and time from wasting. To design a plastic injection mold, one must first identify the components.

Plastic injection mold structure

generally the plastic injection mold structure is as follows:

Mold compartment:

Includes the mold cavity (molding pistil that gives the outer shape of the piece) and the muscle (the molding part that creates the inner form of the piece).

Cavidage plate and muscle plate:

The plate on which the mold is mounted on it is the cavity plate and the plate on which the protruding part is built is called the muscle plate. When closing the template, the two plates are mounted together and create the space between them.

half of the mold that is attached to the fixed part of the mold and the second half, which is attached to the moving part of the injection machine, is the semi -moving. The injection mold may be single -huts or several driles.